Forces Affecting Joint Audits

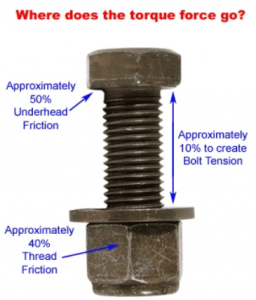

- Frictional and tension forces affect joint audits.

- These forces include underhead friction, thread friction and bolt tension.

Fastener Motion

To audit Torque it is necessary to move the installed fastener. Traditionally , this has led to one of three methods of auditing :

Method 1- First Motion in tightening Direction

In this method , a variable – reading type torque wrench (dial or beam ) is used to apply force to the fastener in the tightening direction until motion is detected.The detected peak torque is regarded as and recorded as the residual torque

This is the most popular & most commonly used method. It is to be remembered however that approximately 80 to 90 % of the torque applied goes to overcome friction & the balance 10 % to 20 % of the torque applied goes towards clamping force.

Method 2 – First motion in loosening Direction

In this method , a variable – reading type torque wrench (dial or beam ) is used to apply force to the fastener in the removal direction until motion is detected. The detected peak torque is regarded as and recorded as the residual torque.

Important Notes :

- The results obtained by this method is always less than obtained under methods 1 & 3 because as force is applied in the opening direction the effect of underhead friction (which is usually 50 % of the torque applied in tightening direction) is less pronounced as the underhead surface of the fastener moves away from the part to be tightened & therefore less torque is recorded in the opening direction.It is to be remembered that installation torque is applied in the tightening direction wherein the underhead friction increases as the fastener is tightened.

- This method is not preferred in an production environment as there is always a possibility of the auditor leaving the fastener untightened after the audit. Normally this method is used for R & D purposes.

Method 3 – Comparision of Rotation End point

In this method the location of a point on the fastener in relation to an item in the grip of the fastener is marked. The fastener is then loosened, and the torque required to rotate the fastener back to the same point in relationship to the marked item in the grip is measured & recorded as the residual torque.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Compiled by Kapil K. Sen (WESTEC)

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++