Currently, the tightness of a bolt/nut assembly is usually assessed by a torque based method, the approach is referred to as torque auditing. Torque auditing is usually completed by one of three torque methods discussed earlier :

Method 1- First motion in tightening direction –

Measuring the torque needed to rotate the bolt/nut by a small angle (typically 2 to 10 degrees) in the tightening direction. This is the most frequently used method of torque auditing.

Method 2 – First motion in loosening direction –

Measuring the torque needed to rotate the bolt/nut in the untightening direction (which will normally be less than the tightening torque).

Method 3 – Comparision of rotation end point –

Marking the position of the bolt/nut relative to the joint, untightening it by an angle of approximately 30 degrees, then measuring the torque needed to tighten the bolt back to the marked position.

Each of these three methods have their deficiencies. The key assumption in each method is that the torque value measured is a true assessment of the tightness of the connection. The critical flaw in each of these methods is the assumption that the coefficient of friction has not changed between the tightening of the bolt/nut and the completion of the checking process. Changes in temperature, humidity and the effects of corrosion after the bolt/nut was originally tightened will affect the friction value and subsequently the torque value but not necessarily the clamp force. A change in the friction condition can make invalid the assumption that the torque value is a true assessment of the bolt’s tightness.

The method described is an attempt to improve upon the present tightness checking methods to allow the clamp force being provided by a previously bolted connection to be assessed and, potentially, corrected. This is achieved by performing a tightening-untightening-retightening sequence on the bolt/nut involving the measurement of torque. This tightening sequence can provide information as to the clamp force provided by the bolt, which allows a better indication of the structural integrity of the joint than existing methods.

![]()

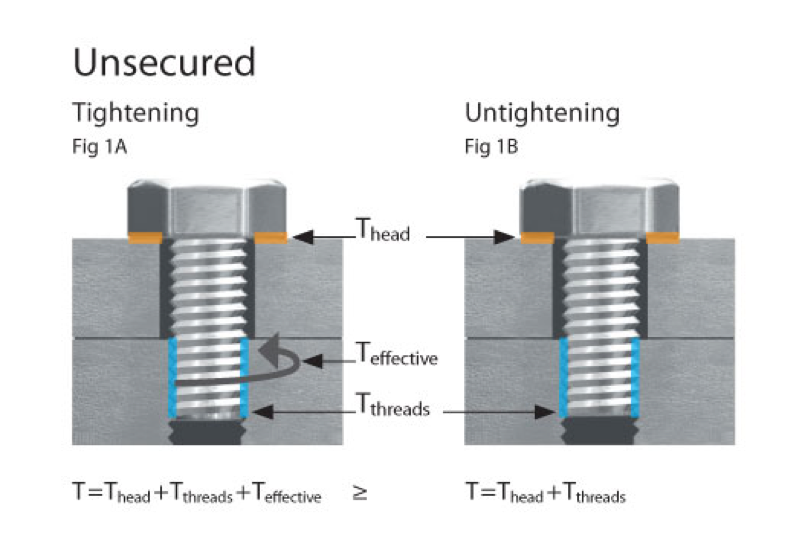

By studying the relationship between the tightening torque , opening (untightening) torque & the pitch of the threaded fastener a simple formula has been derived as shown above.

So for example if on a previously tightened M12 nut/bolt (pitch p = 1.75mm), a tightening torque of 80Nm was measured and the opening torque value was 60Nm, the clamp force would be estimated as being 36kN. The larger the difference between the tightening and opening torque values,the larger was the force present in the bolt.

Explanation :

While untightening, provided that the assembly remains in the same condition, the applied torque has to overcome frictional forces. As a result, untightening a fastener requires a lower torque (see fig 1B). Lower the torque means lower friction & hence larger the clamping force for a specified torque (refer –“Methods of Torque audits” in this section)

To apply this method to establish the tightness of the bolted connection, the torque needed to incrementally rotate the nut in the tightening direction is measured, then measured in the untightening direction, before final retightening.

This method of audit is accurate when coefficient of friction is low – less than 0.08.

For friction values 0.08 to 0.12 this method is a good indicator of bolt load.

At high friction values of >0.25 such as indicated by galvanized bolts without lubricant this method has limited potential.

This method of tightness auditing method is found to be more accurate when –

- Well lubricated fasteners are used that have inherently low friction values.

- The auditing process is conducted after a relatively short period of time after the fastener installation.

This method of tightness auditing would tend to be less accurate when –

- The fasteners are not lubricated and have an inherently high friction, for example, a galvanised finish without a lubricant being used.

- A significant period of time has elapsed since the fastener installation and the operating environment is such that corrosion is likely to occur.

Depending upon the method of applying the torque and knowledge of the friction conditions, the scatter in the bolt load can vary between +/-17% to +/-33%. The variation in bolt load is largely due to the variation in the fastener friction rather than the accuracy of the applied torque value. The typical accuracy of this method of tightness auditing method is well within these limits.

Establishing what load/torque that the bolts in a joint should be tightened to can be problematic for some maintenance activities. This method could, potentially, provide important information about the load that the existing bolts are sustaining – allowing the torque that a new bolt should be tightened to be better estimated.

Measuring the “first motion tightening torque” alone can be a poor indicator of the retained clamp force of the joint. It is frequently used since usually there is no practical alternative. In short, for most applications the conventional torque auditing approach can be effectively used (that is, measuring the torque needed to fractionally rotate the fastener in the tightening direction), this suggested tightness auditing method can also be implemented. A major advantage of this tightness auditing approach is that additional information can be derived regarding the integrity of the joint without a significant change being made to existing working practices.

Establishing the likely retained clamp force present in a joint can be a crucial factor in determining whether the structural integrity of the assembly is likely to be satisfactory, or likely to be impaired. As such, this new approach can be a useful tool in helping to ensure product safety and reliability.

There are limitations to this new approach to fastener tightness checking, principally its accuracy in high friction conditions,but it is a useful indicator as to the retained fastener clamp force in many circumstances.

Acknowledgements : Compiled by Kapil Sen from various technical literature on the world wide web.